The hardware store had all the screws I needed, I love these types of stores.

Sometimes it is best to put a flintlock project down for a day or two to regroup, the patch box was driving me crazy. If I lightly tapped on the box to get a soot transfer the thin metal of the box would deform. It was very hard to get into place.

I decided I needed to breathe some osage dust to clear my head. I have a bunch of mismatched osage billets, while I was getting over some surgery a while back I glued a bunch of these random billets together to make bow blanks.

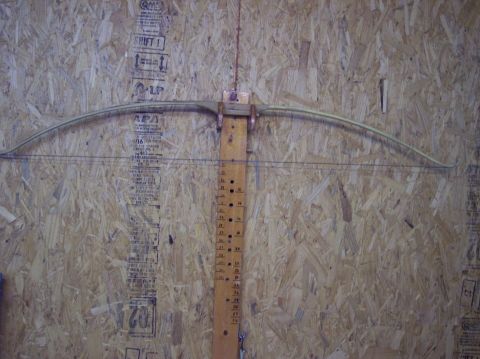

I started a static recurve out of one of these bow blanks months ago but never got it tillered well enough to string it, today was the day. The strange thing about this bow is the limbs go every which way unstrung but straighten up perfectly strung. One limb is tough buttery osage, the other is dark chalky osage. One limb has a big wind shake in the fade, the other limb has drying checks about a foot long in the back, all superglued of course.

Strung without the handle shaped or tillering finished, I think the right (bottom) limb is 1 1/2" shorter than the left. The shadows make the tiller look off but the limbs are pretty closely matched.