I took some pictures to compare this arrowhead with arrowheads different types and materials.

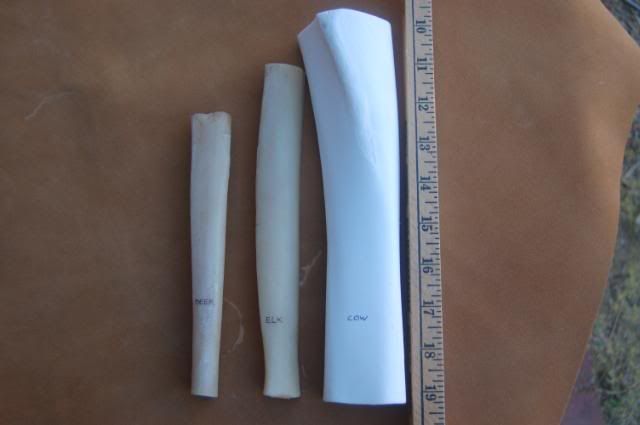

First, a comparison of materials.

Even with different types, the thickness at the end is very similar.

A thickness of 1/8" is possible even with the deer bone.

Comparison of arrowhead preforms:

They have all been trimmed with my band saw.

The deer preform is taken from the widest shard of deer bone (from the smashed bones above).

The elk and cow can easily handle the legal width of 7/8", but not the deer bone...unless I use the largest mule deer bones and cut them on my band saw.

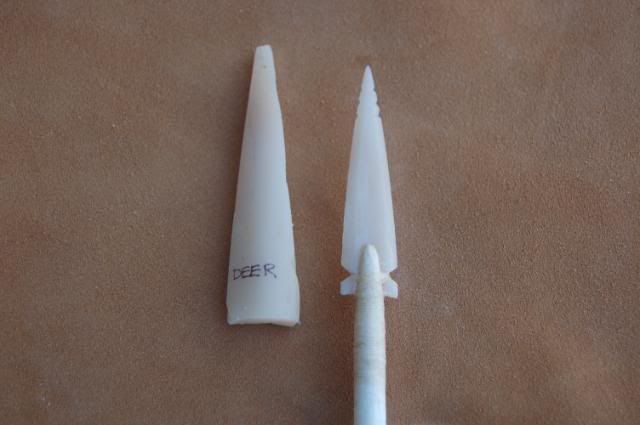

OK, now compared to two other points that have seen heavy use and penetrate very well.

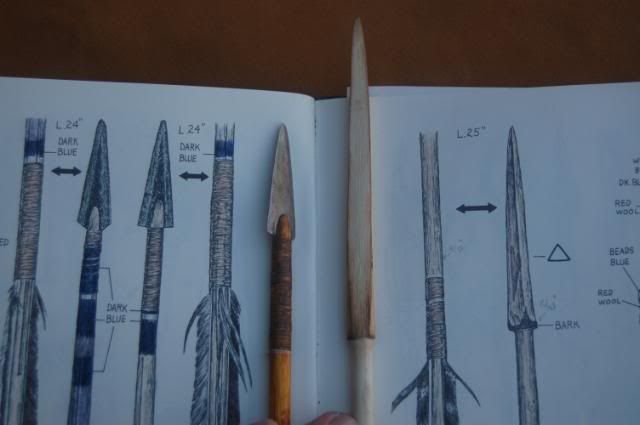

As far as I know (from Laubin) the wooden arrowhead was in common use among the Comanche for hunting.

The problem I encounter, though, is split tips when the arrow hits a hard object.

I imagine if the arrow hits a rib, it will not penetrate far....but I dunno.

The splintered end may still puncture lungs and other organs.

As far as my bone point, I doubt that it will be able to penetrate if it hits a rib.

Here is a deer antler compared to the other points.

It's about the right size for an arrowhead.

My next project is to make a deer antler arrowhead with only stone tools.

I imagine it would take 30-45 minutes to make an antler arrowhead.

The hardest part would be to cut through the antler to release the shaped arrrowhead.

The hole could be made with a stone drill easily, I would think?

In conclusion, I think my bone arrowhead might be a little too long and thin (and therefore too weak) for effective penetration of a deer's rib cage...but I could be wrong. The tip of the point would most likely break off, leaving a jagged edge...and that edge would be very sharp.

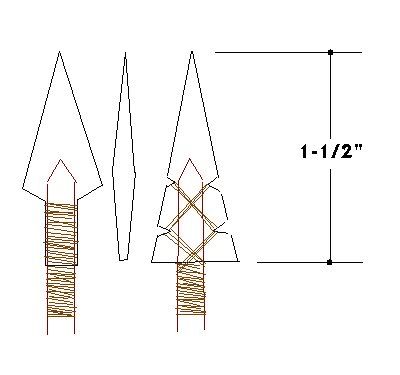

Here are some pics of actual NA bone arrowheads. I think the longest ones are 1-1/2".

It seems to me that these were hafted using lots of glue and very little sinew wrapping.

I've seen archaeologists label the triangular points as "shark tooth effigies".

It would be interesting to know if the NA's actually copied shark's teeth or if the arrowheads were simply more effective with that shape.

Personally, if I was designing a bone point to kill deer, I would want a long hafting area with a diamond-shaped side profile?

Tracy, I think 45lb @ under 20 yards would be a good minimum for taking deer with a narrow, long, bone point. The edges of the blade are not very sharp, compared to steel or stone, so a higher bow poundage would be better in this case. Just my opinion. We can't know for sure unless we perform some tests.