First, THANKS to all for the great info ya'll have posted! I'm up to page 50 something reading past posts and have learned tons and gotten a lot of inspiration. There are many true craftsmen and artists posting.

As a small repayment, a simple gizmo I've found useful for finishing 5/16" straight and tapered shafts:

Just dip it a bit in the spar urethane, push it down and then back up the shaft. Don't worry about the tiny bubbles that result- they dissipate- at least at room temps and RH.

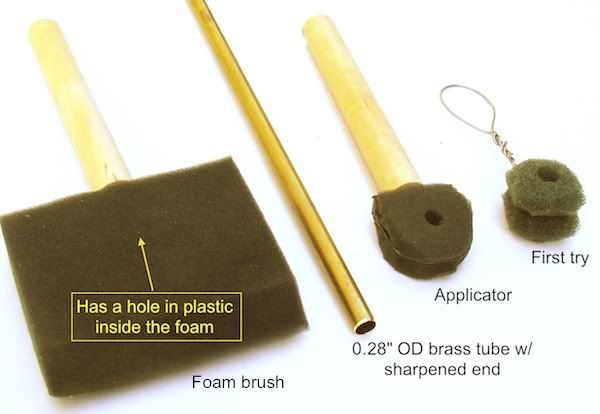

I don't remember where the foam brush was purchased but it came with a hole in the plastic reinforcement that's inside the brush. The hole in the one I used feels around 3/8" to 1/2" in diameter. A brush with foam of a fine texture and, for tapered shafts, a soft texture is probably the best bet. To make a drill for the hole, sharpen the end of a 0.28" OD brass tube with a fine, smooth cut file on the outside edge and deburr the inside edge a bit with a knife. Twist it with very gentle downward pressure by hand thru the foam.

The rightmost gizmo in the photo is the first stab at an applicator. It was made using a chunk of foam used for padding shipment. The foam is much firmer than the that in the foam brush. It did straight shafts well but not tapered ones. The one hacked from a foam brush works better.

Caveats: Might need to up-size the hole in the brush for shafts more than 5/16" in diameter. Might not work as well with finishes other than Helmsman spar urethane gloss. Might not work as well outside of room temperature and RH.

Background: Finishing shafts (and bows too) is my least favorite arrow-smithing task. My favorite finish of late is Helmsman gloss spar urethane. Dipping is messy and the amount of thinning seems to be critical. I've not had success with a Little Dipper clone I cobbled together- maybe it works better with lacquer but doing it indoors that's too smelly indoors. Brushing gives good results but tedious. Ditto for wipe-on urethane.

Again, THANKS to all for your posts!

c.d.