I thought some of the new bowyers might be intrested in seeing how two billets are spliced together at the handle.

Wood billets are so much easier to obtain good clean wood from, but a lot of folks will not or cannot utilize them because of the splicing that's needed. Done properly, it is as strong as a single piece of wood and can have many advantages. You can also induce reflex or deflex right out of the handle which can be an asset depending on the design of the bow. "sister" billets will have the same density and characteristics on each limb most of the time unless you happen to have reaction wood, which is a different topic altogether...

Ok...lets get started. First get the desired billets (tree stave or milled lumber) and make a surface parallel to the intended back of the bow nice and flat for about 8-10" however the thickness of the billets are. For this tutorial I'm using lumber so I don't have pics of the raw stave type...sorry. What this does is allow the cuts for the splice to be 90 deg to the back of the bow so the splices fit together neatly.

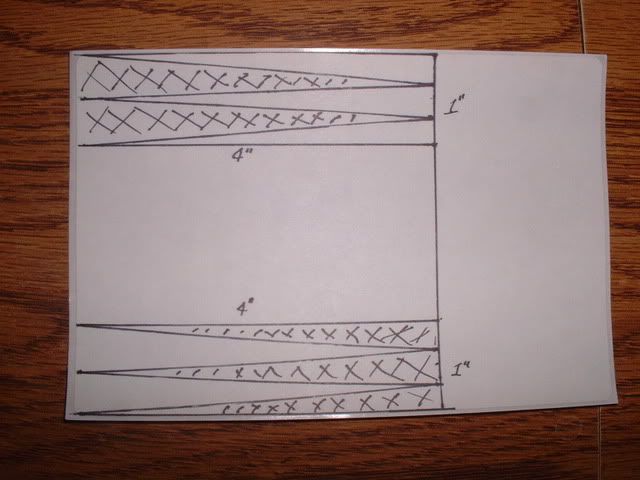

Now you need to prepare your template. I use the sticky peel off mailing labels. The adhesive peels off easily and without residue and they are cheap. Take a ruler and mark off (2) 1" X 4" rectangles as shown. Draw off the division lines and connect the marks as shown.

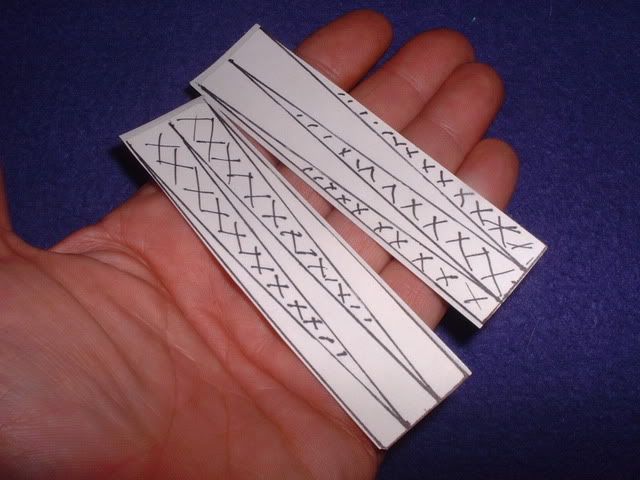

Cut the templates out with scissors. You should have two templates that look like this.

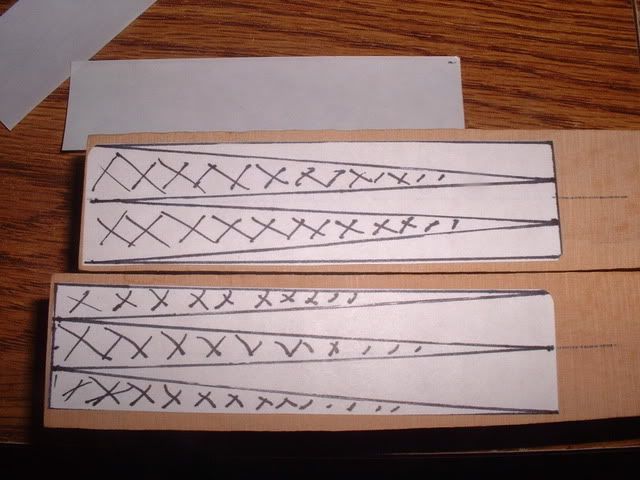

Now take you billets and strike a center line to line up the handle to tips. Peel off the label and align the marks with the centerline you made and stick it down.

Check to make sure you have oriented them correctly by holding them end to end (been there and done that...

)

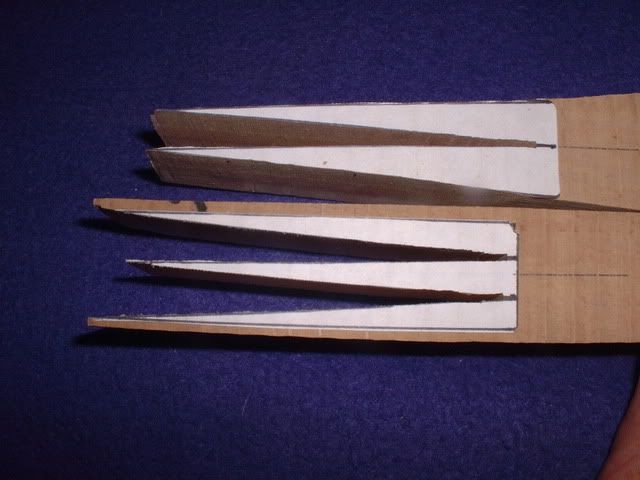

Now go to your band saw and cut to the lines of your template. This is what you should have when your done. You can fine tune with other tools if needed to get a proper fit. If your good with a band saw they usually come out pretty close.

Now, stick them together and and check your fit. Now all that is needed is some good glue and your ready to go.

If your fit just doesn't want to go right...you can boil the ends for about 30 min and clamp them together for a tighter fit. Let them dry clamped for at least 3-4 days and completely before gluing together.

Hope this helps some one utilize some of the good bow wood that can be found as billet material. It's not hard to do. After you have done a few you'll be using wood you never thought possible.

Take care...

Roger