Well, Mullet's been after me to do a buildalong, so here it is.

I recently started work at a door/window shop, where we mainly use vertical grain douglas fir but also from time to time use hardwoods. The other day while stocking up some shelves, i saw a dirty old piece of wood with the words Grey Elm written on it. It was 4 feet long, 1.5" by 7.5", with a serious bow near one end. I asked the boss and he was kind enough to give it to me. So I ran to the table saw, cut it into four chunks 1.75" wide, and then to the bandsaw to resaw these into "billets" 4 feet long, 11/16" thick, by 1.75" wide.

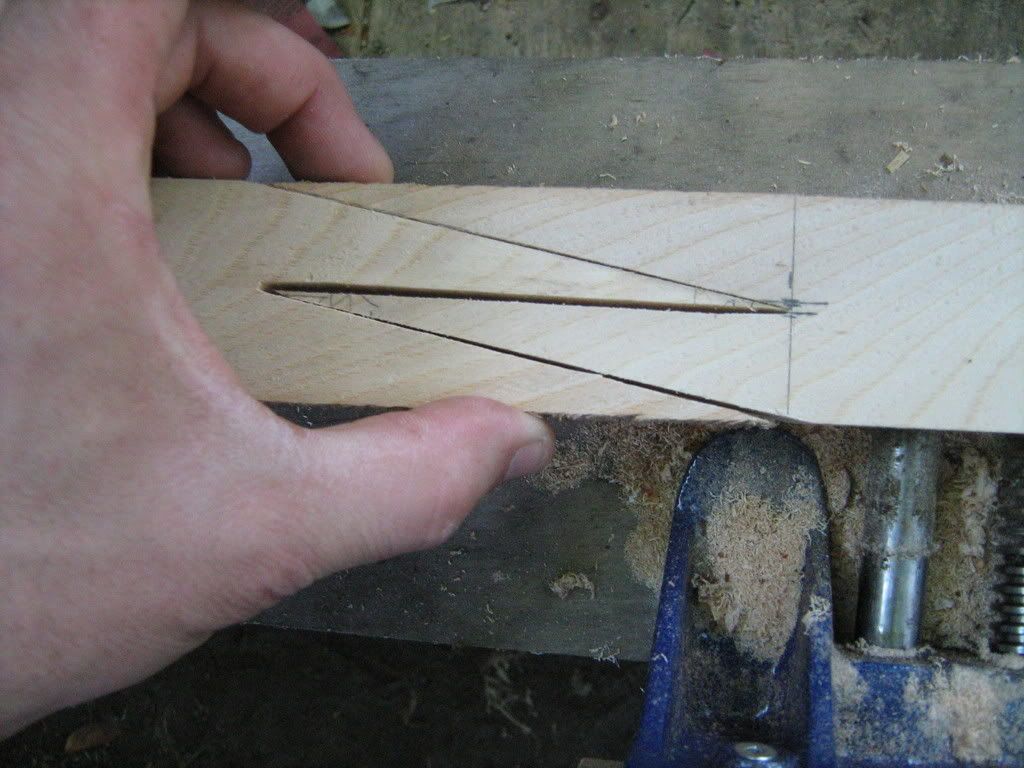

Today I cut out the z-splices using John Strunk's method from TBB1: stack the billets so that backs are both facing up, tape them together, draw the outline on the top one, and cut with the bandsaw on the lines. I only used 3 pairs, even though I had 4...one of the pieces didn't turn out so good (bandsaw accident). Here's what they look like.

Here are a couple set together in prep for glueup. You can see there's a good-sized gap at the center. To make up for the gap, I used a rasp to generate some shavings which i later mixed with the epoxy to bond the pieces together. The other two sets of billets lined up pretty good.

Here is a set of taped-together billets resting on a table. The back is up, showing what kind of reflex these bows will have when the staves are glued together.

Now, as for the joints. The outside cut on the z-splice was easy to true: after cutting it on the bandsaw, I laid the outside cut on the beltsander for 2 seconds: voila! Perfectly smooth. The centerline cut was also easy: just used a fence on the bandsaw. But for the inside angled cut, I had to use a different method to clean up the lines.

Here is the epoxy I used, and a little cup with elm shavings that I used to buff up the epoxy on the one pair of billets that was too gappy.

HEre is that pair glued up and clamped.

And finally (for today) since food seems to be so important to everyone here, here's a shot of what I ate for supper tonight.

PLANS FOR THESE STAVES

These staves are quite long, 68" I think, and as I said, 1.75" wide. According to Paul Comstock, that should be good for 60 # of pull. The reflex is not severe, only moderate, which should make tillering fairly easy. I think I'm going to floor tiller each one, and then apply 1/8" of hickory backing over them. I just want something continuous spanning the bow along the back to protect the splice. I have only spliced one bow before, a (very) short HBO, so I guess I'm a bit shy about letting the splice do all the work without a brace.

I will make at least one holmegaard out of these...maybe 2...out of all the bows I've made, I think my HBO holmegaard is my favourite...

One of the bows I plan to give to my boss, who gave me the wood, as a thank you present. Maybe he will hang it in the shop...who know? Maybe he will shoot it.

Just as long as he doesn't shoot ME with it!