Thanks for the tips Bownarra.

I'll admit that I feel like I have a child's understanding of how all this works, but a guy has to start somewhere.

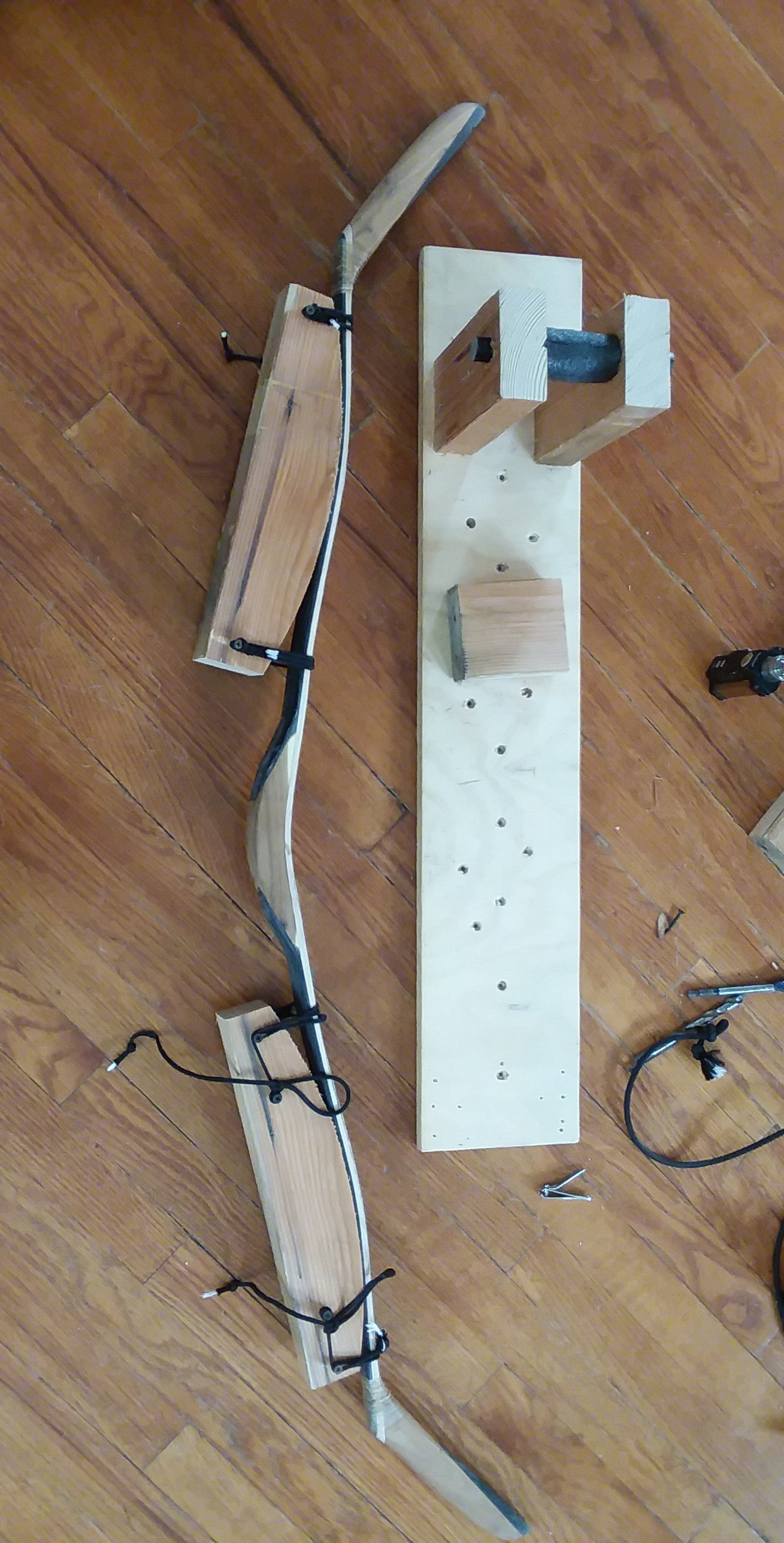

The horn does go up the fades but during glue up the cracked when I clamped it, right at rhe bottom of rhe fades, I think because the transition was too abrupt. I used G Flex epoxy and made sure I had enough to ooze and fill any gaps and it did ooze out of the cracks so maybe that helps. The core tapers about an inch forward of the fades and I'm going to do the same with the horn to take some stress off of the areas where the crackkng occured and move the working portions of the limbs forward a bit. Don't know if this will work, but the only other option is to reclaim the sinew and start over...which I figure I can do if the bow fails anyway so might as well experiment. I've already resigned myself to the fact that the bow won't survive but I've learned at least a few things during this process.

The cores are hickory as it's the only wood that I've found that can hold up to how dry it is here, all other woods I've used with sinew, including osage and bamboo, get riped apart by the drying sinew.

I made some crude tepeliks yesterday and so far so good. Need to reduce some draw weight, my target is 50 pounds at 28 inches but in exercising the limbs it feels way more.