I had a request awhile back to do a build-a-long for the fish arrow I made for the member trade. This is/was my first build-a-long and it was more of an effort than I anticipated. I'd like to thank all the members who take the time to give instructions like this. I had no idea the time involved and how much more difficult it makes the project. Just when you get a groove going you have to stop for pictures. It's also very hard to build anything and take pics at the same time. I've had my third arm on back order for years. I'm wondering if they're discontinued. Because of the unexpected amount of work involved this will be presented in installments. Please be patient, I'll try not to take too long.

With that out of the way, I present Dakota Kid's primitive fish arrow build. We'll assume those reading have a basic arrow building knowledge. I'll be leaving out part that already have instructions posted, like straightening boo, preparing sinew, and cutting self nocks. I tried to keep things as primitive as I could. The only modern materials used were TB3, food coloring, and a drop of airbrush paint. Pics of the actual trade arrow can be found in that thread. This is one I'm making for a trade with trapper rob, but is for the most part identical. The design was based on some images of inuit fishing arrows I found online.

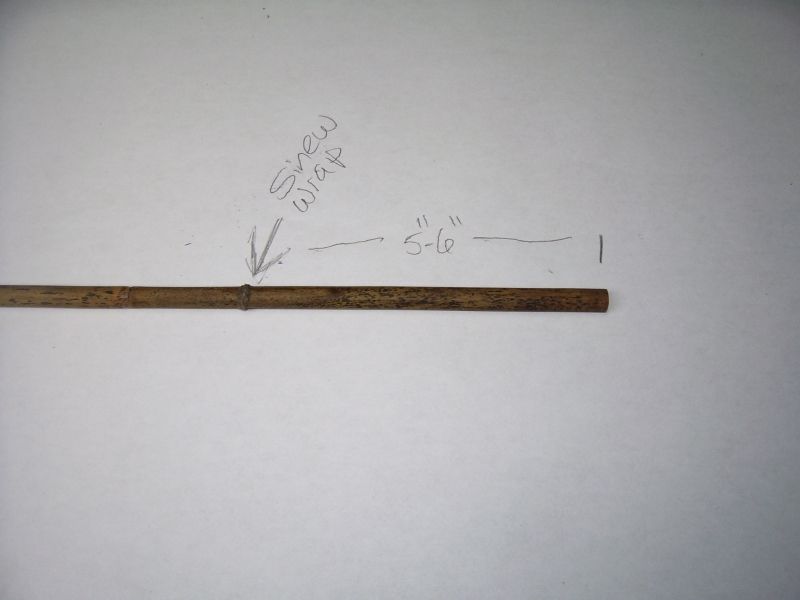

Step one, get a nice straight boo shaft about 6" longer than you typically use for your draw length. Measure six inches back from what will be the point end and do a nice tight sinew wrap. Stay away from hide glue as this arrow will be getting wet. TB3 works great. I rehydrate the sinew then soak it int he glue. Allow the glue to dry before proceeding. You could also do your self nock at this point as well.

Step two, drill out the hollow in the boo shaft. Make sure you drill almost as deep as your sinew wrap.

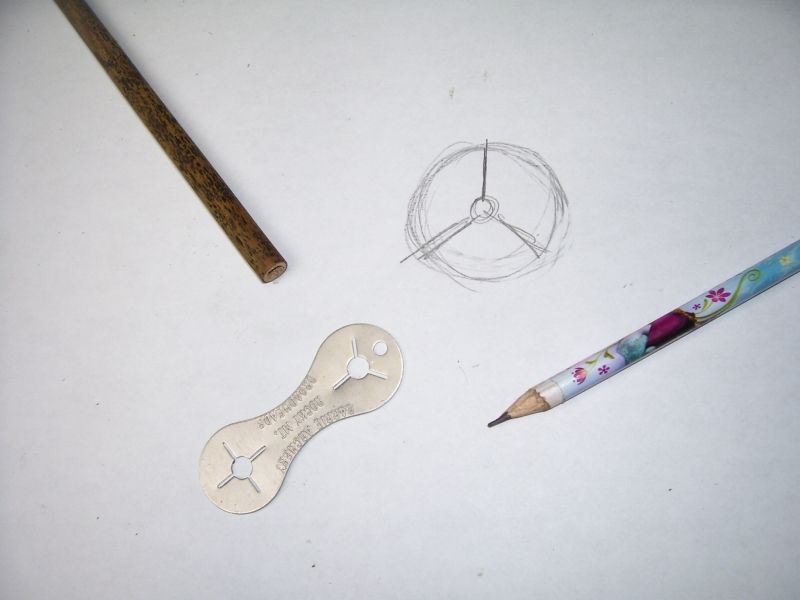

Step three, marking the boo and cutting the three prongs that will make the points. I usually just eyeball the division lines, which I mark on the end of the shaft. If you don't trust you inner ruler, a standard 3 blade broadhead wrench works great for a template.

Slap a piece of tape down the side of the shaft to help keep the kinfe from drifting. Make your cuts with an adjustable saftey razor with the blade depth set shallow enough you don't cut throught to the opposite side wall. Do this for all three cut lines.

Step four, Splitting and spreading the boo prongs. Find a small, hard, round object. I'm using the shaker ball from an empty spray paint can. Work the ball into the hollow of the shaft. You may need to make a few small cuts to completely free any fibers that may have been missed on the first cut.

Work the ball as far back to the sinew as you can without cracking the prongs. You'll feel when you run out of room. Make sure the prongs are spaced evenly before you continue becasue the next step will fix them in place.

Step five, cleaning up the boo prongs. Now that the ball is in place you have easy acess to the center and sides of the prongs. Clean up the backside and square off the edges.