Time to pin the stock to the barrel so everything will be held firmly in place for lock inletting. On these rifles the barrel supports the stock.

First locate where you want the pins so they won't interfere with the ramrod pipes which are pinned to the stock but not the barrel.

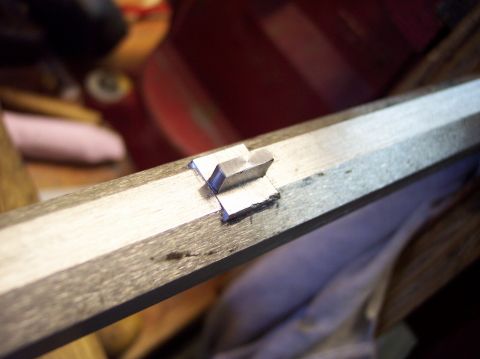

The lugs I will dovetail into the barrel are .052 thick so I need to cut a .052 deep dovetail in the barrel.

I mark .050 on the sides of my barrel flat and take out as much material as I can with a hacksaw.

I square everything up first before I cut in the dovetails.

I make my dovetail about .010 undersized so I can file it larger a little bit at a time for a tight lug fit.

A nice tight fit;

Cleaned up and ready to cut the next one, I will put three underlugs evenly spaced to pin the stock to the barrel.