I finally made it back. I chose to use bloodwood for the handles on these knives. For the sake of time, I am going to concentrate on just one knife for now. I can finish the other one after the build along. I rip off a couple pieces that are just wide enough to feel comfortable on the knife and trace the pattern for the handle onto the wood. Make sure the sides that touch the metal are perfectly flat so you get the best fit.

Then I run the piece of wood through the bandsaw and cut them about 1/16" larger than the handle pattern.

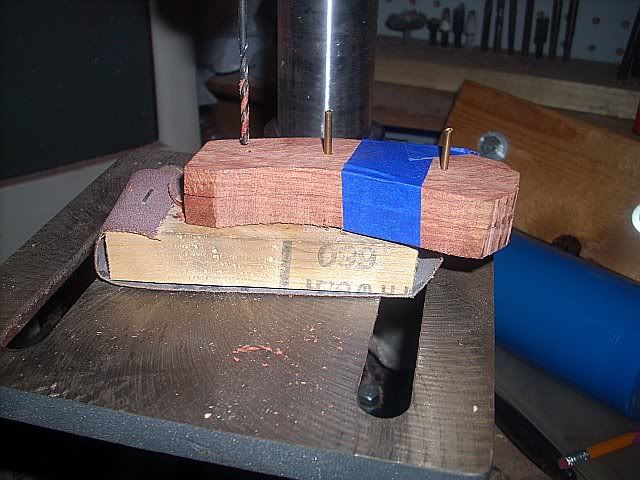

Once I get them lined up with the handle, I mark the holes for the handles on the wood with a sharpie marker and throw a piece of tape around the wood to hold it together while drilling the holes.

To help keep them from slipping around and getting the holes out of alignment, I drill one hole and add a pin, then drill the second hole and add the second pin, and finally the third.

Now I switch to a sanding drum and remove the tool marks and round the edges. While I am at it, I sand in a couple of finger grooves at the front.

The next step is to clean up the blade some and tape the handles. I cover the handles with tape except for where the adhesive will be. While I am taping, I press down where the pins will be inserted. That makes it easier to find the holes and insert the pins while everything is covered with epoxy.

This is the first time I am using this epoxy, so I don't know how long it will take to dry. It said industrial grade heavy duty, so it should hold everything together. I mix it on old plastic lids. When the leftover is dry, it peels right off and the lid can be reused.

The epoxy said that no clamping was need, but I did it anyway. I wanted a thin glue line. With the pins inserted and the clamps on, I had some left over so I decided to finish a couple broadheads that I wanted to try.

I have a few that are about ready for some heandles. It looks like I have my work cut out for me.

As soon as the epoxy is dry, I will be ready for the final shaping and clean up.