blade is sanded to 320 grit wet paper.

not flawless but still pretty nice.

next a very small amount of gunstock wax is applied to the blade and then taped up both to protect the blade and yourself.

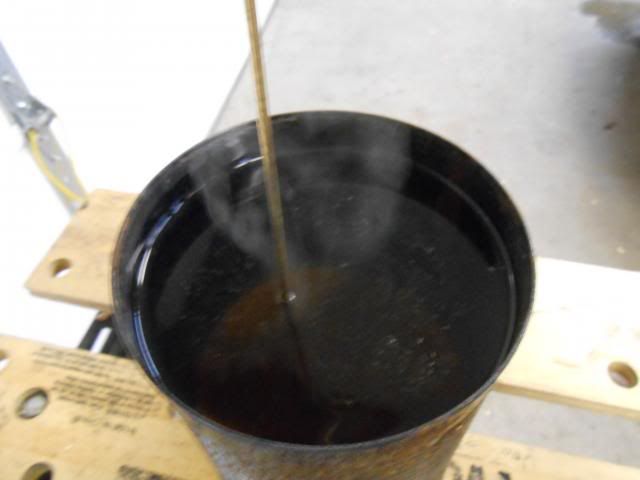

here I anneal the 1/8 inch brass rod that will be used for pins.

by holding the brass rod vertically and heating to red hot then promptly dunking in cold water.

next we cut the brass into 1 inch length and add a bevel both ends all the way around.

I then select a piece of wood for the scales.

I chose a piece of curly maple recycled from a pallet.

here is the left and right sides of the handle traced on the board.

I labeled them wrong in the pic but that's easy enough to change (no harm no foul).

we then cut out the rough scales using what ever tools you have and clamp them one at a time to the blade.

keeping as close to the original tracing as possible.

I then drill the 1/8 holes one at a time and press a pin into each one after drilling.

next operation is to shape the first scale closer to finished dimension and the apply to the blade engaging the pins only enough to locate.

I then clamp to the second scale and remove 1 pin and drill thru the whole thing.

replacing each pin as soon as the hole is drilled.