That's what ear protectors are for. They keep the ears warm too, if your shop is cool.

Haha, yeah I have been finding myself wearing mine all the time anymore. My basement (where my power tools are) don't get no heat except the holes here and there in the crappy heating duct. I am pretty happy with the results I am getting with my bandsaw yall (exclamation mark,

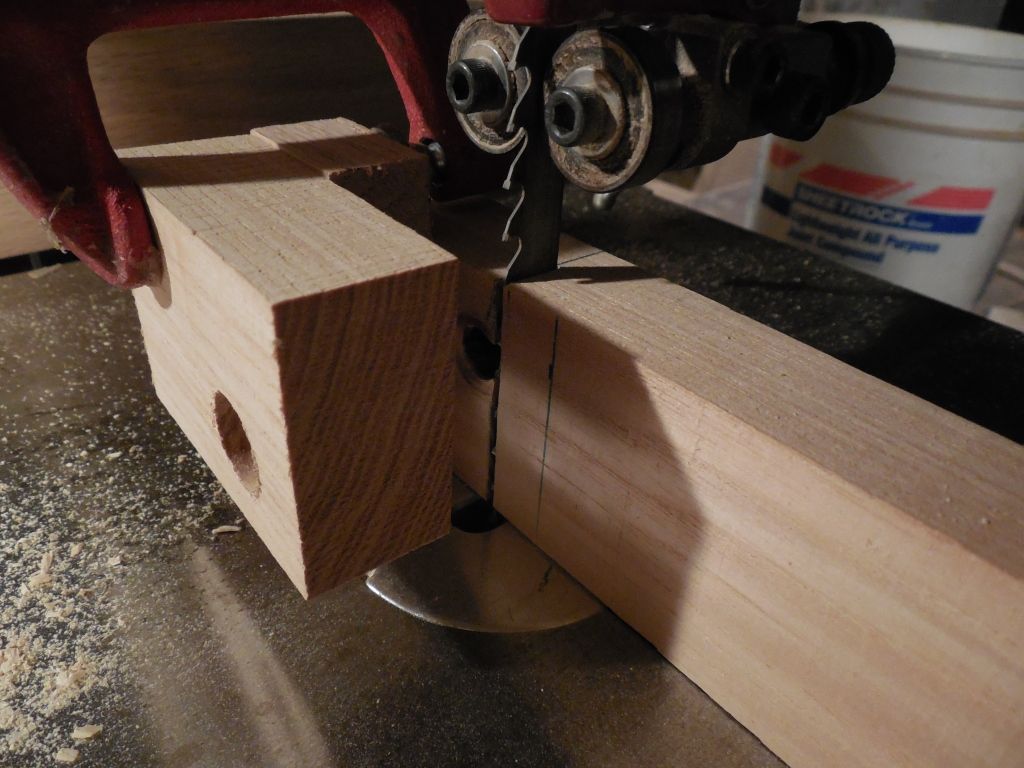

). It is no where near as good as you can get with a router I would guess, but it is the best I have got out of anything I have tried yet. What I got going on is I cut my stock at 7/16" wide, and spin it into a 3/8" hole. The tips of the blade are sticking out just a tiny little bit, to where you can barely feel them. I wasn't having the best luck guiding the stock in without getting flat spots until I added the infeed guide hole (which I cut with a 5/8" guide hole, which fits the 7/16" stock pretty good). It took me a bit of playing around to get the stuff looking ok though. The blade I am using is a lenox carbide higher tension thicker something or other, I thought it was a trimaster but it doesn't look like it. It has teeth similar to tablesaw though, not like a normal hook or rake tooth. Might have something to do with it, whether it is a good thing or bad thing I don't know.

This is right after cutting

You can see the tiny saw marks here, I could probably play with it till I get niltch, but I am happy at least being able to cut without tear out

Above is my attempt on the bandsaw, below is my best results from messing with the router, lol

. I'll figure out the router sooner or later, it does seem to be the best way.

I guess I am going to put an arm on it, than put another guide hole or two, and see if I can turn out some 3/8 shafts. My plan is to taper the nock end to spine them, but I am kinda confused on something I read. Does tapering the shaft effect the spine of the arrow, verses not tapering? I read on here that you need to drop 10 lb or so from the spine of an arrow shaft if you taper it, is this true? So if it spines 40, but it is tapered, than you can assume it shoots like a 30 spine shaft, all other things being equal?