Let's talk about sharp rocks. If you are anything like me, you like to use the points you create and if they ain't sharp there is no point (no pun intended.) I have been working on my technique for the last couple years and I would like to share what I've come up with and I'd be interested in seeing what others do as well. I'm no expert, so don't misconstrue the info I'm providing as anything but an apprentices perspective. That bein said, I use what I make and I'm killing deer. So let's take a close look at the fine edge of knappin.

I start off with a preform that is already thinned and most if the major irregularities have been removed. Platform edge fairly even and lightly ground.

At this point, I will use a flaker with a finer tip as the flakes I'm removing frm this point on will be small and very precise. Normally, I start at the tip and with a light touch remove the first flakes at a somewhat steep angle. You are not trying to remove mass here so it is not important for the flakes to travel. As you move down the continuous platform with regular flakes the direction of force will change a little so that your flakes travel across the field of the point.

Once you have removed flakes from the entire edge you should be left with regular micro deltas that need to be nipped off. Keep the same orientation of the rock to the pad and with a light touch take the very tips of these protrusions off. DO NOT GRIND! In fact, I don't touch the edge with a grinding block from this point on. It goes without saying, that your point should already be at the size and shape you are looking for in the end.

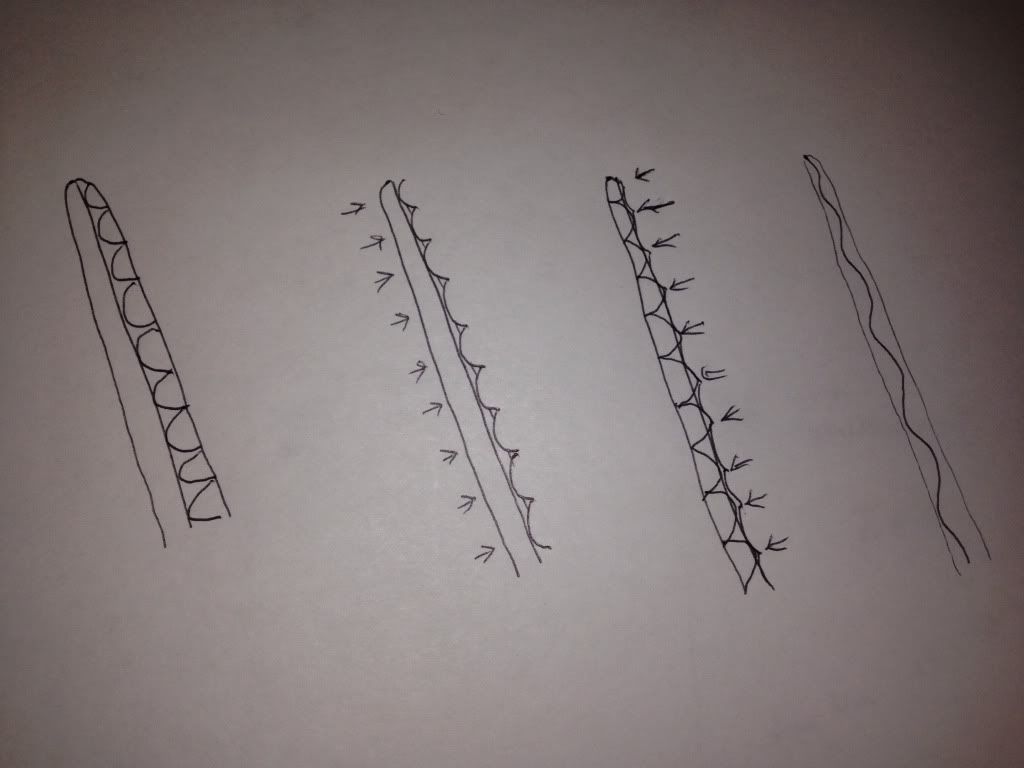

Once removed, flip the point and starting from the tip you are gonna remove flakes from side B. Here's the trick... The reason for removing the micro protrusions from side A was to make the platform strong enough to withstand the pressure from side B. The tip of your flaker should be pressing on the miniature platform that you just created. Here's a sketch depicting the 4 steps...

Now this also creates a slight disadvantage with regards to the center line and so you need to decrease the angle of pressure so you don't have trouble with step fractures. But the alternating flake removal leaves a subtle wavy edge that has not been touch and is therefore very sharp.

After both sides have been sharpened I try to leave the edge alone and only make minimal adjustments with my horshoe flaker. Once the tip has been made into a needle point and the notches are added the rock is ready to work.

So that's my technique. Let's see what everyone else is doing.