Here's some pictures of a bow I recently made. It's a hickory backed ipe, 66 1/2" from nock to nock, 45# @ 28".

Piece of hickory and my ipe, both 68" long, cut, sanded to 80 grit, and ready to go. The hickory is around 1/8" or so, a little less I think, and the ipe is 7/16" thick.

Bloodwood power lam, 13 1/2" long:

And some maple bloodwood and ipe I will use for the built up handle:

Here I am using a template to draw out the profile on both the piece of ipe and the piece of hickory. I think the measurements are 68" long, 1 7/16" wide for 4 1/4" on each side of center (so a 8 1/2" handle), tapering to 1/2" tips:

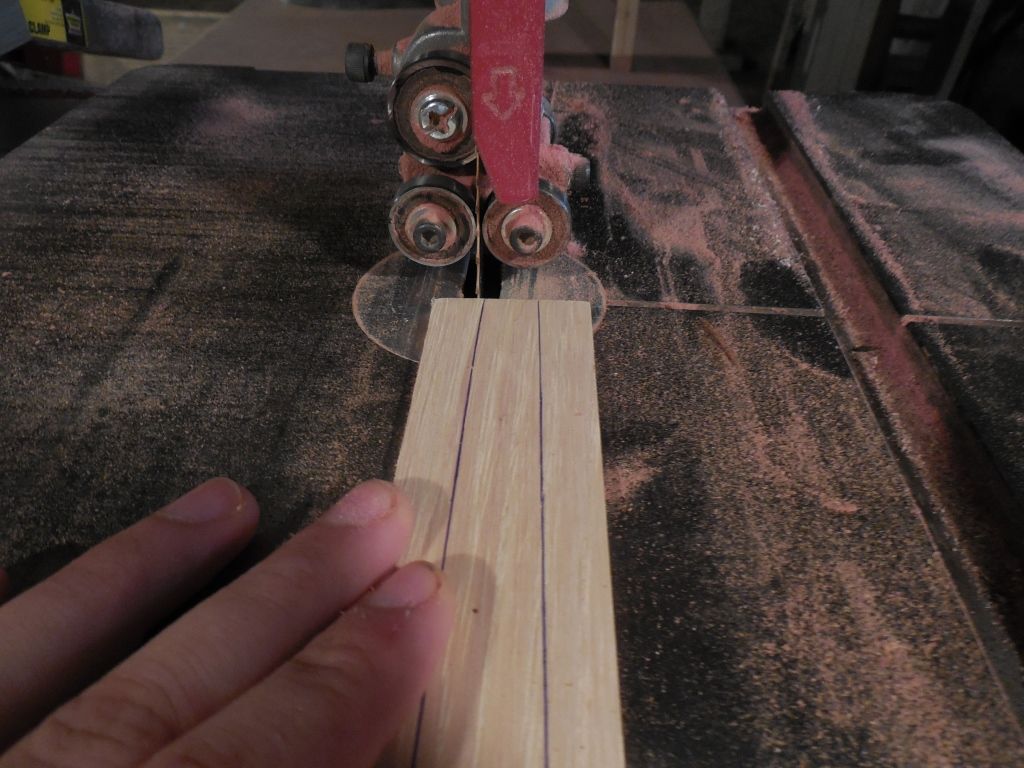

Staying well outside the lines, I cut it out with my bandsaw and and then sand it to the line (carefully) with my belt sander to get it as close as possible:

Here's a pic of how thick my ipe is:

...I don't show it here but I measure the tip on the end of the ipe to about 1/4", and than use the belt sander to do a thickness taper on the belly until I reach the 1/4" thickness, or close. I don't know why I need to do this with a pyramid taper anyhow, but for some reason I do, I wonder if it is due to the narrowness of the pyramid taper, or the fact I glue in reflex. Anyhow, I usually floor tiller my belly while I do this, checking for an even bend: