Oh, I forgot to show a picture inbetween here. As I'm making the bow from one horn, one tip is going to be made from the solid tip of the horn, while the other will be made of the scull-section of the horn. The part of the horn closest to the scull is usually pretty thin, and was so in this case also. The horn was some inches longer than the finished bow, so I cut off a little at the base of the horn, to get rid of some of the thinnest part of it. Still, one tip of the bow will have more sinew than horn because there was not enough horn thickness. In the next picture you can see the hollow part of the horn, which accounts for the thin wall in it. The picture was taken after boiling and straightening it.

After this, I cut off the waste of the sides of the laminate, and shaped the width profile, while also adjusting the thickness. I was aming for 7mm thickness at the middle, and 6mm from mid-limb to tips. One tip will taper even more, down to 4mm. I'm sure it will not be a problem to compensate with some extra sinew, even though it might give it some extra reflex that will have to be corrected in the finished bow.

After shaping the laminate further, I boiled it once more, and clamped it to the bench again. As you see from the picture below, it is starting to look like an outline of a bow, even though there is still some sideways bend in one tip.

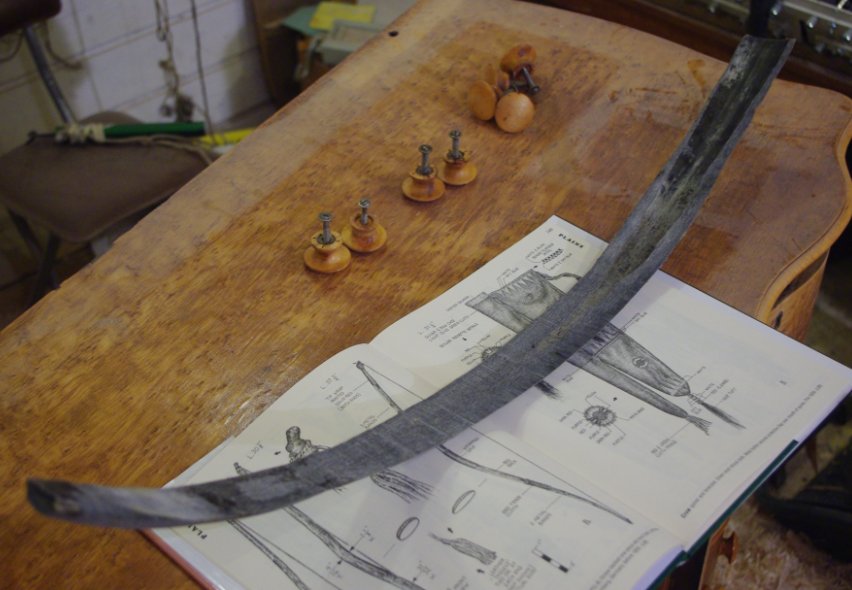

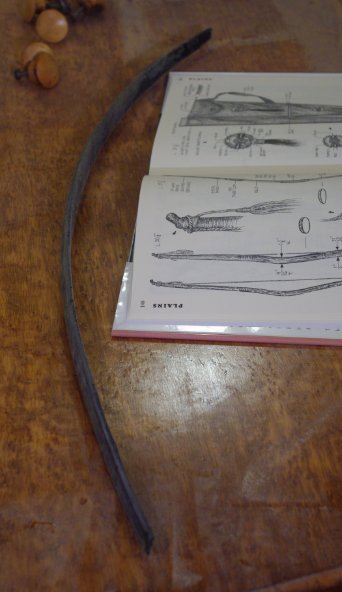

The next image shows the amount of reflex the horn had after the second round of straightening. I don't worry about straightening the horn too much, because it will regain all of it when I do the sinewing. I'm pretty confident the tips will touch or even cross after I have put on the last layer of sinew. Most of that will have to be stressed out of it to make the bow shootable, but it will make sure that the bow will perform well. You may also recognize the page in one of the encyclopedias, with the drawing that I am working out from.

After some more shaping, I scraped the whole horn. Horn works great with a scraper, and it is a joy to see the horn change into the black shiny surface. It is really a pretty material, even though sheep horn would be somewhat more interesting. The picture below shows the width profile of the laminate after it has been scaped. You can also see the two sanding machines I used to shape it, in the background. Far from primitive, and pretty smelly. But my head is full of bows that I "need" to make, and not enough spare time... It is also a very safe method of shaping horn as there is no stress on it from using adzes, and it does not need to be clamped to something while using rasps. It can of course all be done with hand tools too.

The next two pictures show the laminate as it was when I finished for the evening. Pretty much ready for sinew. I will do some final touch-up of the cross section and make sure the limb taper is pretty good first. The horn can be tillered to some extent. It is very flexible, although I will not risk bending it to full-draw without sinew on the back. It might well have survived that though.

So, that was all for tonight. It will be very interesting to put sinew onto this little bastard. I bet it will curl up pretty quickly, although I will intentionally put on the first layers of sinew somewhat sloppy. As far as I have seen on original american-indian sinew backed wooden bows, the sinew layer has been a little rough. It also means that I don't have to put as much effort into preparing the sinew strands for the first build-ups of sinew, which is a welcome time-saver.