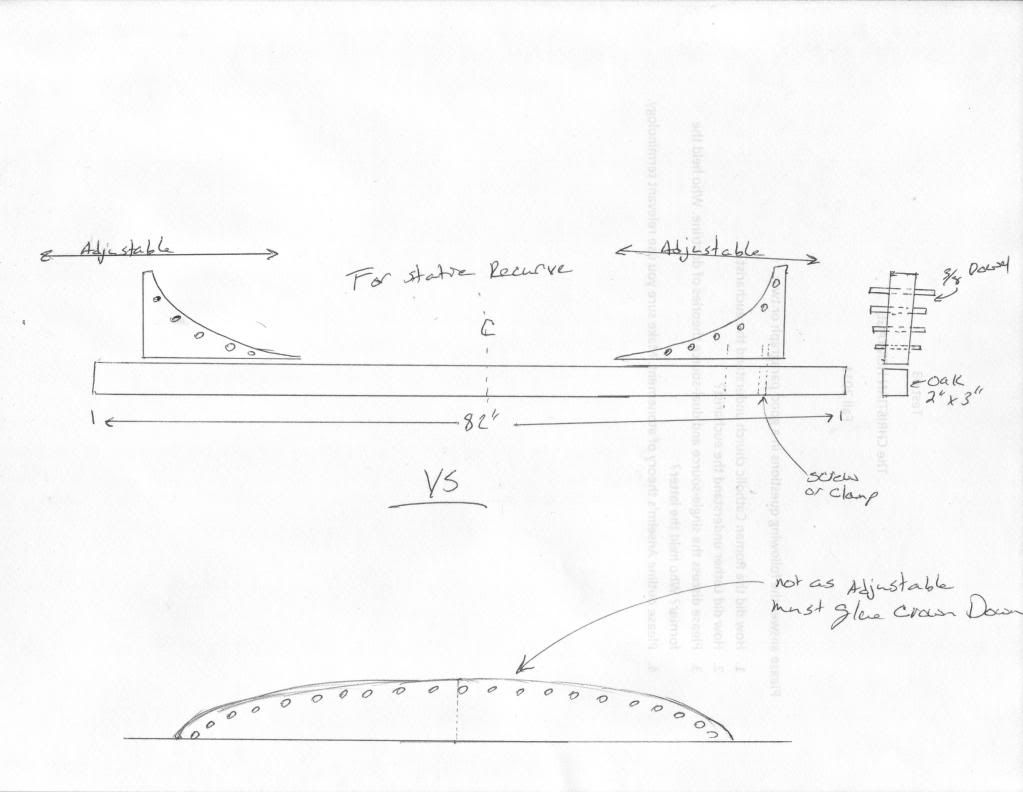

So most of my bows are laminated. Bamboo backed at least. I want to do a recurve next. Given that I like the bamboo backing I kinda need to glue it up in teh Crown up position. I have made crown down froms and prelaced them with light cotton rope which holds things nicely and lets me do crown down but it's not my favorite. Primarily because those sorts of forms are not that versitile. If you varry the length of your bow then you also loose curvature at the tip. Talking about laminated construction Not heat bending the tips seperately.

I have had problems with just using space blocks and clamps on a straight bar. I've done a few R/D bows this way and have had 3 come out with "issues". While in the oven the wood softens and the curves get screwey. Usualy they look different despite being clamped the same.

So I thought that since I'm laminating the bows I can take advantage fo that tendency for wood to soften in the oven pluss with this I can vary the bow length with greater effect. I may need to do some aspects of glue in a 2nd stage but I'm ok with that. Things like brush knocks. If for example I wanted included a spliced in recurve extension Under the backing I could use it here. I can just make different interchangeable curves and adjust them for shorter or longer bows. I use Bike rubber to wrap my bows down. I simply spiral wrap the body to the recurved portion then I'll start zig zagging across the pegs till it's pulled down tight. 4Hours in the oven with some Urac and it should be solid. Then If I want any belly laminataions It will be a 2nd gluing course.

What do you think?

later I'll do some actual steam bent tips but I'd rather work up to that. I'm more comfortable with the laminated methods for now.